The PPTD is a sealed filter-bag centrifuge for ethanol botanical extraction and clean solid–liquid separation. Load biomass into the zipper bag, run bidirectional agitation to improve extraction, then drain and spin-dry in the same closed vessel—helping cut down solvent loss and odor release. An explosion-proof motor with VFD control plus a PLC touchscreen keeps each run stable and repeatable. All wetted parts are food-grade stainless steel for easy cleaning. Available in multiple sizes from 6 to 520 lb per batch (dry plant), with manual valves standard and electric-valve automation optional.

PPTD Sealed Filter-Bag Centrifuge (Botanical Extraction + Dewatering)

Application: Ethanol-based botanical extraction; filtration and dewatering in one unit

Process: Load dry biomass into a zipper filter bag → add solvent → bi-directional agitation for extraction → drain → high-speed spin-drying for solid–liquid separation

Closed Operation: Helps reduce solvent evaporation and odor escape

Control & Drive: Explosion-proof motor, VFD for adjustable speed profiles, PLC + touchscreen HMI for repeatable recipes

Build: Food-grade stainless-steel wetted parts for corrosion resistance and cleaning

Operation Options: Standard manual valve setup; optional electric valve for automatic operation

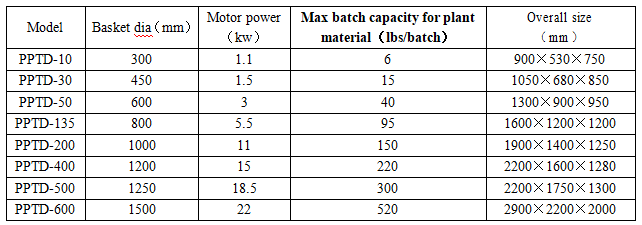

Capacity Range: Multiple models covering 6–520 lbs per batch (dry plant)

- The whole operation process is controlled by frequency conversion, you can choose manual or automatic operation, the loading and dehydration speed can be set according to different materials for the best, ,it can separate many varieties of mixture if choosing suitable filter medium.

- It can be used according to the requirement, applicable to the airtight, explosion-proof, poisonous, harmful and flammable materials.

- It is widely used in plant extraction, medicine, pharmaceutical intermediates, vitamin, Chinese medicine, amino acids, antibiotics, pesticides, herbicides, etc;

- The part of contacting materials adopts stainless steels, it has a good corrosion resistance, the material can use titanium, PE-RT,2205 duplex stainless steels etc if containing chlorine ion and other special materials.

- Easy maintenance: Simple structure for easy cleaning and upkeep, reducing operating and maintenance costs.

- Food-gradematerials: Every machine uses food-grade materials and durable, hygienic stainless-steel welded construction. This ensures easy cleaning and supports operation in a sanitary washing environment. Compatible with multiple CIP detergents/cleaning agents.

1 year Full Factory Warranty

What is the typical cycle time?

About 30 minutes per 40 lbs run depending on biomass preparation, spin profile, and target solvent recovery.

Can I run cryogenic ethanol with this centrifuge?

Yes. The unit is compatible with cryo-range ethanol processes to preserve cannabinoids and terpenes. Pair with insulated lines and an appropriately sized chiller for best results.

Do you offer installation or some operatation help?

The installation and operation of the centrifuge are very simple—don’t worry!If you encounter any issues, we can offer remote guidance via video to help you through the process.

Is the motor explosion-proof?

Yes — the drive system uses an explosion-proof motor. Follow all local codes and ventilation requirements.

DISCLAIMER: Our closed-loop systems are intended for legal purposes only. Operate in a well-ventilated area and in accordance with all local, state, and federal laws. Qualified professionals should install and operate this equipment.

Double-layer stainless-steel

Better cold retentiondrum for maximum low-temperature insulation. Optional chilled-water recirculation system greatly reduces ice consumption—saving you time, energy, and money.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

This is the heading

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.